19 1 Metal Gearmotor 37dx68l Wiring Diagram Arduino

Different power sources for the motors and Arduino. But the Arduino needs 7-12V.

How To Test Motor Encoder With Arduino Osoyoo Com

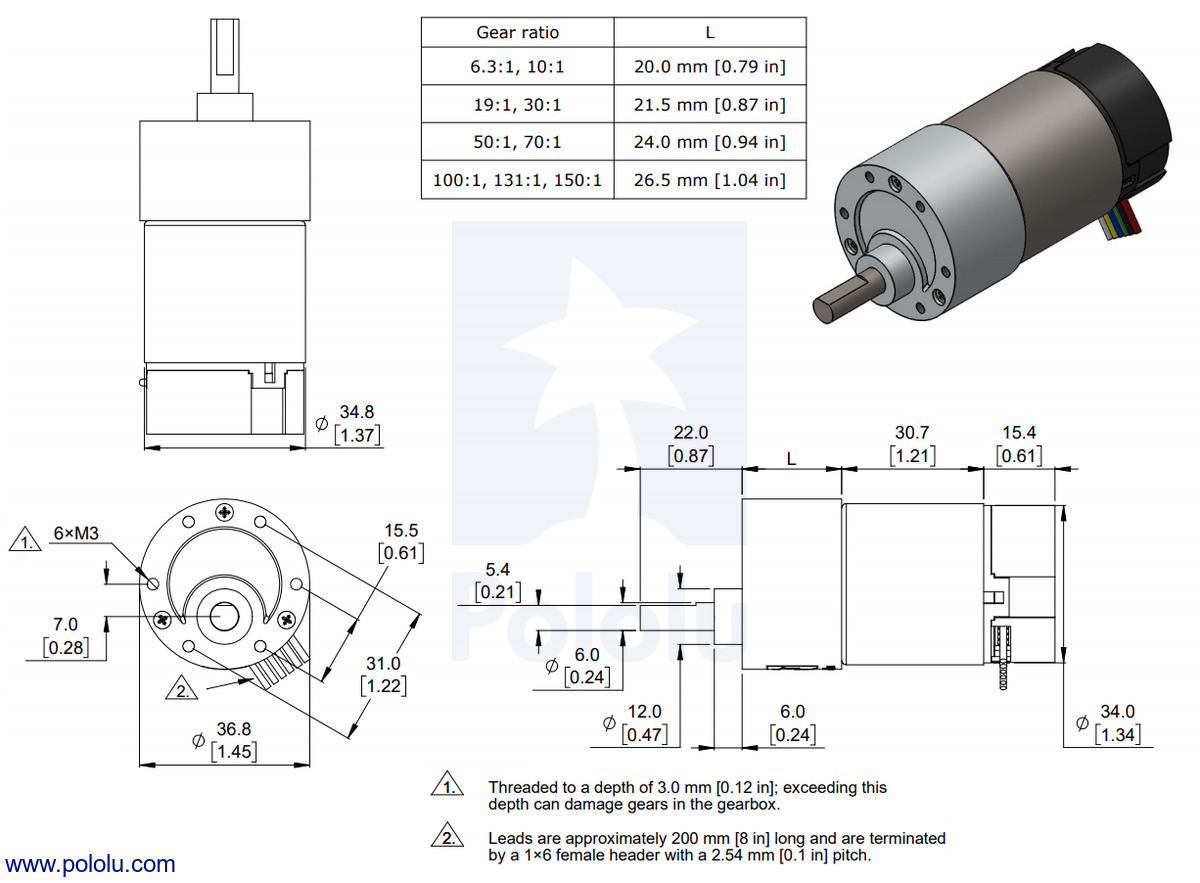

191 Metal Gearmotor 37Dx68L mm 12V with 64 CPR Encoder Spur Pinion 301 Metal Gearmotor 37Dx68L mm 12V with 64 CPR Encoder Spur Pinion 501 Metal Gearmotor 37Dx70L mm 12V with 64 CPR Encoder Spur Pinion.

..jpg)

19 1 metal gearmotor 37dx68l wiring diagram arduino. This carrier board for STs VNH5019 motor driver IC operates from 55 to 24 V and can deliver a continuous 12 A 30 A peak. Encoder Metal Gearmotor 12V DC High Speed 300RPM Gear Motor with Encoder for Arduino and 3D Printers. Other pins approximately also at this values.

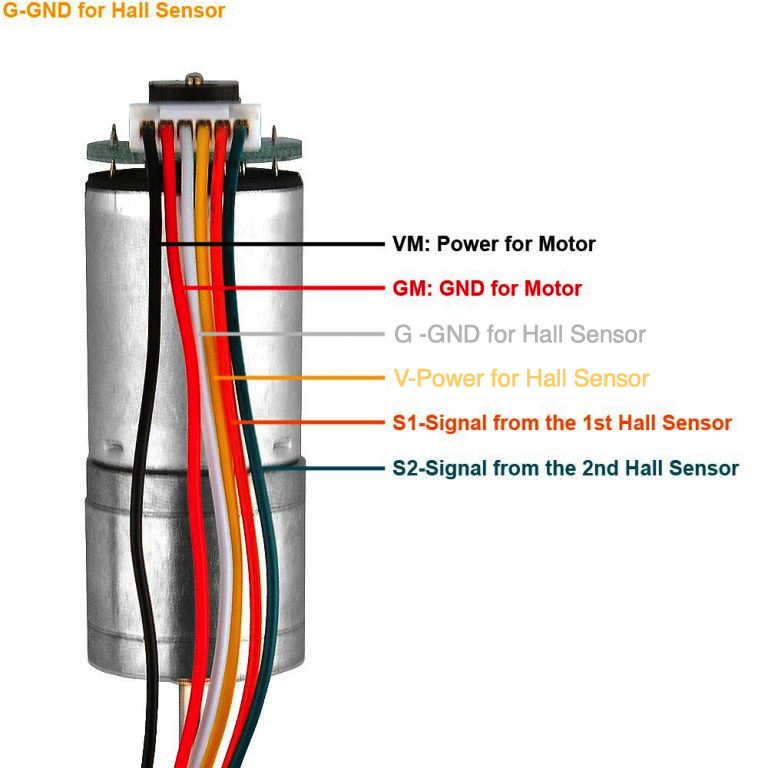

This gearmotor is a powerful 12V brushed DC motor with a 501 metal gearbox and an integrated quadrature encoder that provides a resolution of 64 counts per revolution of the motor shaft which corresponds to 3200 counts per revolution of the gearboxs output shaft. May 21 2021. Wiring up the encoders is pretty simple.

A 4 AA battery pack provides between 55 and 65V and can give a lot of current which makes it good for the motors. How can I connect me high power motor encoder controller to arduino. It works with 25 to 5 V logic levels supports ultrasonic up to 20 kHz PWM and features current sense feedback an analog voltage proportional to the motor current.

I need a wiring diagram. See the diagram below for details on wiring up the encoder for motor B and repeat for motor A. To simplify this tutorial we are going to use two different power supplies.

The gearmotor is cylindrical with a diameter just under 25 mm and the D-shaped output shaft is 4 mm in diameter and extends 125 mm from. Encoder wires connect to the Arduino not to the motor driver. Google has many special features to help you find exactly what youre looking for.

The Arduino is going to be powered by the USB connection while the DC motor is going to be powered by a battery pack. I wired together a controller using two joysticks with the detent springs remove harvested from a used toy drone controller plus two discrete potentiometers to control the gripper and the rotating base. So i connected them to Arduino UNO pins and only 1 relay worked.

IN1 IN2 IN3 IN4 Vcc and GND. There is a 4-channel relay module. This is the motor Im using.

The gearbox is composed mainly of spur gears but it features helical gears for the first stage for reduced noise and improved. It has 6 pins. 191 Metal Gearmotor 37Dx68L mm with 64 CPR Encoder.

Step 1 Powering The Breadboard. Place 3 wires in a 1 3 pin connector housing in the following order. 1813 Windows Store 18420 Windows 10 Board.

Find many great new used options and get the best deals for Gear Motor with Encoder DC 12V 500RPM Ratio 120 D Shaft Code Disk Gearmotor at the best online prices at eBay. Pololu - 2041 Metal Gearmotor 25Dx65L. Tools Home Improvement.

This gearmotor consists of a high-power 12 V brushed DC motor combined with a 46851 metal spur gearbox and it has an integrated 48 CPR quadrature encoder on the motor shaft which provides 224886 counts per revolution of the gearboxs output shaft. One of them is to measure the rotation of a DC gearmotor. Bemonoc Encoder Metal Gearmotor 12V DC Low Speed 60 RPM Gear Motor with Encoder for Arduino and 3D Printers BEMONOC 25GA370 DC Encoder Metal Gearmotor 12V High Speed 150RPM Gear Motor with Two-channel Hall Effect Encoder for DIY Parts.

1001 Metal Gearmotor 37Dx73L mm with 64 CPR Encoder. BEMONOC DC Gear Motor with Encoder 24V DC Low Speed 25 RPM Metal Encoder Gearmotor for Arduino and 3D Printers Visit the Bemonoc Store 10 out of 5 stars 1 rating. Note that the encoder pin OUTA needs to be connected to a hardware interrupt pin digital pin 2 or 3 on an Arduino Duemilanove or Uno.

Im gonna to connect 6 pcs of 4-channel to Arduino Mega 2560 R3. Buy Encoder Metal Gearmotor 24V DC High Speed 130RPM Gear Motor with Encoder for Arduino and 3D Printers. Bemonoc Encoder Metal Gearmotor 12V DC Low Speed 60 RPM Gear Motor with Encoder for Arduino and 3D Printers BEMONOC 25GA370 DC Encoder Metal Gearmotor 12V High Speed 150RPM Gear Motor with Two-channel Hall Effect Encoder for DIY Parts.

Post a real wiring diagram so we can see what changes might be needed. Black red and yellow. CQRobot 2701 Metal Gearmotor 37Dx725L mm 12V with 64 CPR Encoder.

501 Metal Gearmotor 37Dx70L mm with 64 CPR Encoder. Encoder Setup and Wiring. May 17 2021.

Search the worlds information including webpages images videos and more. While there are more efficient ways to do this this will allow the tutorial to work with as many DC motors as possible. Some people solve this by using a separate power source for the Arduino usually a 9V battery.

Wiring for a single motor and encoder. Do not add a. Along with built-in protection against reverse-voltage over-voltage under-voltage over.

Hello I have two dc motors 341 Metal Gearmotor 25Dx52L mm HP 6V with 48 CPR Encoder. Does Icc needs more current for 4-channel. With Mounting Bracket 40 RPM80 kgcm 1112 ozin D-Shaped Gearbox Output Shaft is.

30 1 Metal Gearmotor 37dx68l Mm With 64 Cpr Encoder Helical Pinion Australia

..jpg)

30 1 Metal Gearmotor 37dx68l Mm 12v With 64 Cpr Encoder Helical Pinion Opencircuit

Amazon Com Cqrobot 70 1 Metal Gearmotor 37dx70l Mm 12v With 64 Cpr Encoder With Mounting Bracket 157 Rpm 28 Kg Cm 389 Oz In D Shaped Gearbox Output Shaft Is 16 Mm Long And 6 Mm In

30 1 Metal Gearmotor 37dx68l Mm With 64 Cpr Encoder

..jpg)

30 1 Metal Gearmotor 37dx68l Mm 12v With 64 Cpr Encoder Helical Pinion Opencircuit

..jpg)

30 1 Metal Gearmotor 37dx68l Mm 12v With 64 Cpr Encoder Helical Pinion Opencircuit